2025 New Product Launch RFID Anti-Metal Tags for Surgical Instruments(Shenzhen Yukai)

Shenzhen Yukai Intelligent Technology Co., Ltd. Presents the 2025 New Product —

RFID Surgical Instrument Anti-Metal Tag Product Introduction

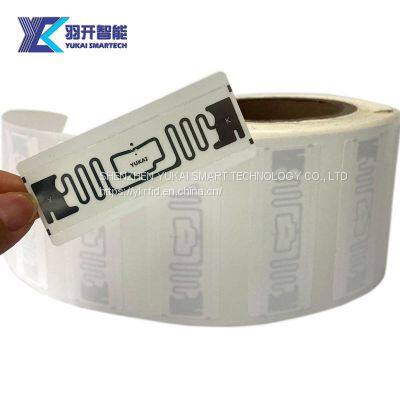

Radio Frequency Identification (RFID) anti-metal tags are specially designed for metallic environments, effectively addressing the performance degradation of traditional RFID tags on metal surfaces. These tags are becoming increasingly vital in the management of surgical instruments.

II. Technical PrinciplesAnti-Metal Design Features

Special Isolation Layer: Built-in shielding material to prevent metal interference with RF signals.

Optimized Antenna Design: Unique antenna structure enhances read/write performance on metal surfaces.

High Dielectric Constant Material: Special substrate reduces electromagnetic field disruption from metal.

Operating Frequency

Typically UHF band (860-960 MHz), balancing read range and anti-interference capability.

Some applications use HF band (13.56 MHz) for short-range precise identification.

Instrument Tracking & Identification

Unique Identification: Each tag stores a unique ID for individual instrument tracking.

Rapid Inventory: Batch scanning improves inventory efficiency.

Usage Records: Tracks usage count, sterilization cycles, and other critical data.

Sterilization Management

High-Temperature Resistance: Withstands 134°C steam sterilization.

Sterilization Cycle Logging: Automatically records sterilization cycles to ensure safety.

Expiration Alerts: Flags instruments requiring maintenance or replacement.

Surgical Workflow Optimization

Surgical Kit Management: Quickly verifies instrument completeness in surgical trays.

Real-Time Location Tracking: Reduces time spent searching for instruments.

Usage Analytics: Optimizes inventory based on usage frequency.

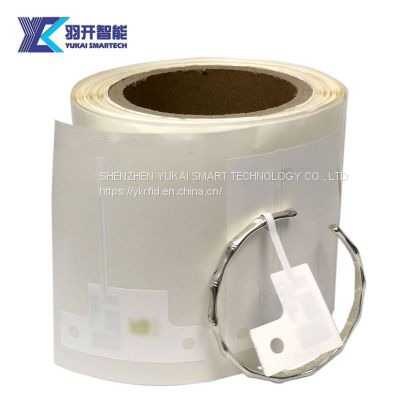

Physical Characteristics

Size: Compact design, as small as 4.5 mm.

Material: Medical-grade corrosion-resistant, compliant with ISO 10993 biocompatibility standards.

Encapsulation: IP68 rating, waterproof and chemical-resistant.

Performance Parameters

Read Range: UHF tags up to 1.2–1.5 meters.

Temperature Range: -40°C to +250°C (special models).

Lifespan: ≥500 high-temperature sterilization cycles (customer-tested).

Data Storage

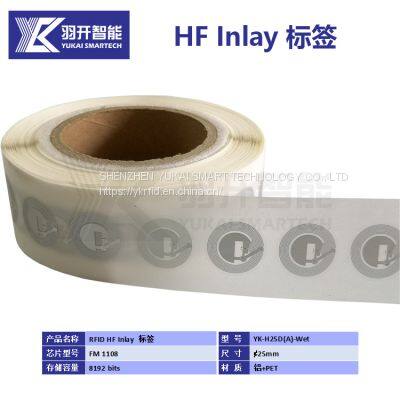

Capacity: 512 bits to 8 Kbits.

Read/Write Cycles: ≥100,000.

Security: Supports password protection and encrypted communication.

Hardware Components

RFID readers (fixed & handheld).

Antenna arrays.

Middleware devices.

Anti-metal tags.

Software Functions

Instrument lifecycle management.

Sterilization records.

Inventory alert system.

Data analytics & reporting.

Compatible Systems

Hospital Information System (HIS).

Operating Room Management System.

Central Sterile Supply Department (CSSD) System.

Asset Management System.

Efficiency: Reduces inventory time by over 80%.

Error Reduction: Cuts instrument loss/misplacement by 95%.

Compliance: Meets medical regulatory requirements.

Cost Savings: Optimizes usage and extends lifespan.

Patient Safety: Ensures sterilization compliance, reducing infection risks.

After implementing RFID surgical instrument management in a top-tier hospital:

Instrument prep time decreased by 60%.

Sterilization pass rate reached 99.9%.

Instrument loss rate dropped by 90%.

Annual procurement costs reduced by 25%.

Smaller tag designs.

Integrated temperature sensors for sterilization monitoring.

AI-powered predictive analytics.

Blockchain for full lifecycle traceability.

Avoid mounting tags on critical functional areas of instruments.

Regularly inspect tag integrity.

Consider pre-installed RFID tags for new instruments.

Establish protocols for damaged tag replacement.

RFID anti-metal tags revolutionize surgical instrument management through digitalization and intelligent solutions, significantly enhancing efficiency and safety—making them essential for modern smart hospitals.

About Shenzhen Yukai Intelligent Technology Co., Ltd.

Founded in 2009 and headquartered in Shenzhen—China’s Silicon Valley—Yukai Intelligent is a high-tech enterprise specializing in the R&D, design, and manufacturing of RFID smart electronic tags, providing comprehensive IoT RFID tag solutions.

Leveraging Hong Kong’s global perspective and Shenzhen’s R&D expertise, Yukai Intelligent utilizes advanced flip-chip bonding and composite equipment, with a complete in-house production line for RFID tags. The company offers customized RFID solutions and holds multiple proprietary technologies, serving industries such as electronics, apparel, food, pharmaceuticals, logistics, retail, and more.

Committed to innovation, precision manufacturing, and quality excellence, Yukai Intelligent stays at the forefront of IoT advancements, collaborating with partners to drive the future of smart connectivity!